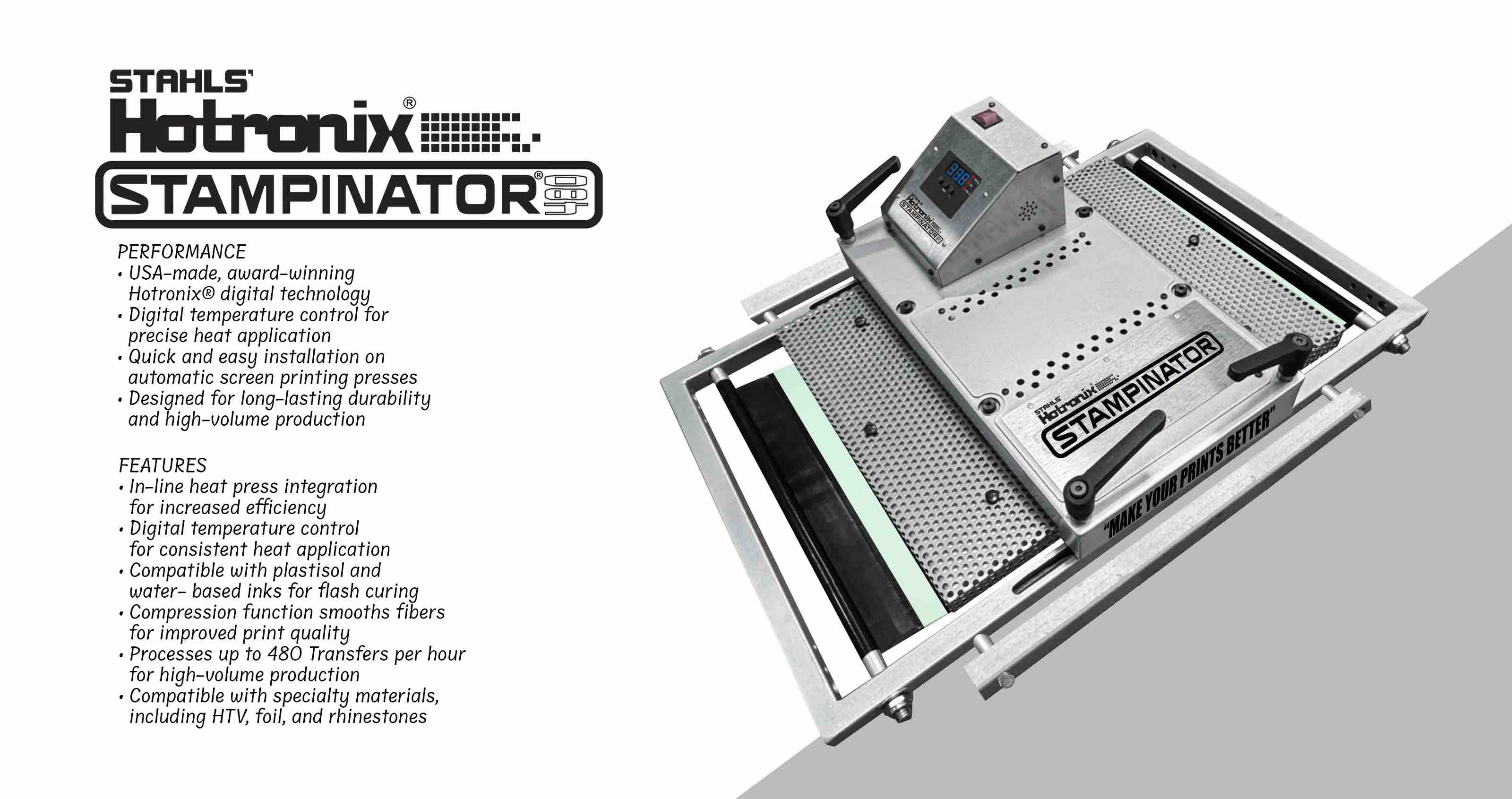

Stampinator 480 Powered by STAHLS' Hotronix

Stampinator Products

-

-

240V Stampinator 480

See MoreThe 240 volt version of the Patented Stampinator 480 can improve your screen print quality and labor efficiencies as a dryer or high volume inline heat press.

-

Stampinator 480 Closeout

See MoreThe 240 volt version of the Patented Stampinator 480 can improve your screen print quality and labor efficiencies as a dryer or high volume inline heat press.

-

Stampinator-M

See MoreThe Patent Pending Manual Stampinator will improve your screen print quality and labor efficiencies as a flash, dryer or high volume inline heat press. Watch these videos for more information.

-

Just Stamp It Class

See MoreImagine if you could increase your production by 4X, while saving $ on consumables, and increase the quality of your prints, all at the same time!

Stampinator Testimonials

BOOK A LIVE DEMO TODAY!

Book a virtual demo today for a live demonstration!

Live demonstration by video | All your questions answered | Transform your press

Recent Blog Posts

View all-

STAHLS’ Hotronix® Signs Partnership with Stampi...

Carmichaels, PA. January 28th, 2025 – STAHLS’ Hotronix®, the world's leading heat press manufacturer, announces an exclusive manufacturing and distribution agreement with Stampinator™. The Hotronix® and Stampinator™ partnership brings together...

STAHLS’ Hotronix® Signs Partnership with Stampi...

Carmichaels, PA. January 28th, 2025 – STAHLS’ Hotronix®, the world's leading heat press manufacturer, announces an exclusive manufacturing and distribution agreement with Stampinator™. The Hotronix® and Stampinator™ partnership brings together...

-

How To Set Up And Use The Stampinator-M

The Stampinator-M is a versatile tool for screen printing and DTF (Direct-to-Film) transfers, designed to enhance precision and ease of use. Here's a step-by-step guide to setting it up and...

How To Set Up And Use The Stampinator-M

The Stampinator-M is a versatile tool for screen printing and DTF (Direct-to-Film) transfers, designed to enhance precision and ease of use. Here's a step-by-step guide to setting it up and...

-

Why the Stampinator Produces Better Quality Prints

In the competitive world of screen printing, the quality of the final print is paramount. While traditional methods such as flash and conveyor dryers have been the industry standard for...

Why the Stampinator Produces Better Quality Prints

In the competitive world of screen printing, the quality of the final print is paramount. While traditional methods such as flash and conveyor dryers have been the industry standard for...

-

Why The Stampinator Flashes Better Than a Tradi...

In the ever-evolving world of screen printing, efficiency and quality are paramount. Traditional methods such as a flash dryer have long been staples in the industry. However, a new technology...

Why The Stampinator Flashes Better Than a Tradi...

In the ever-evolving world of screen printing, efficiency and quality are paramount. Traditional methods such as a flash dryer have long been staples in the industry. However, a new technology...